Rigofill ST-B infiltration module

Rigofill ST-B infiltration module

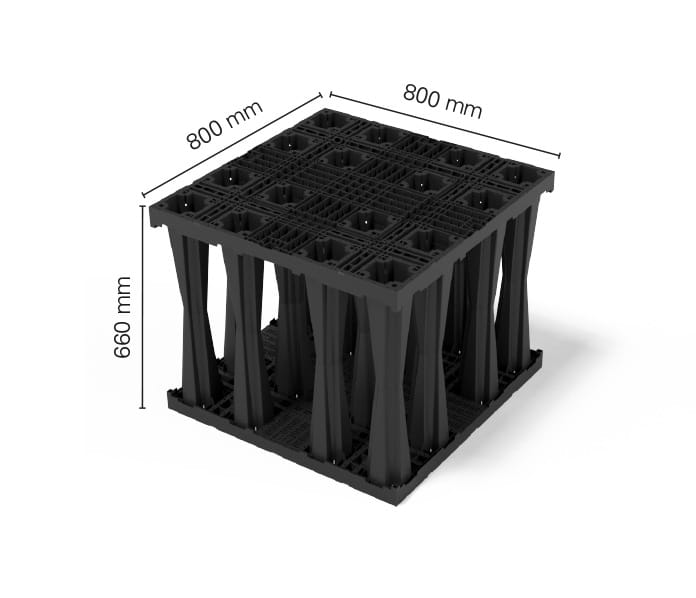

Where medium-heavy traffic loads are to be expected above the infiltration system, it is possible to use the Rigofill ST-B system. These ST-B modules are less expensive than the Rigofill ST modules. This choice makes the most cost-effective solution available for your situation at any time.

The optimum system for every situation

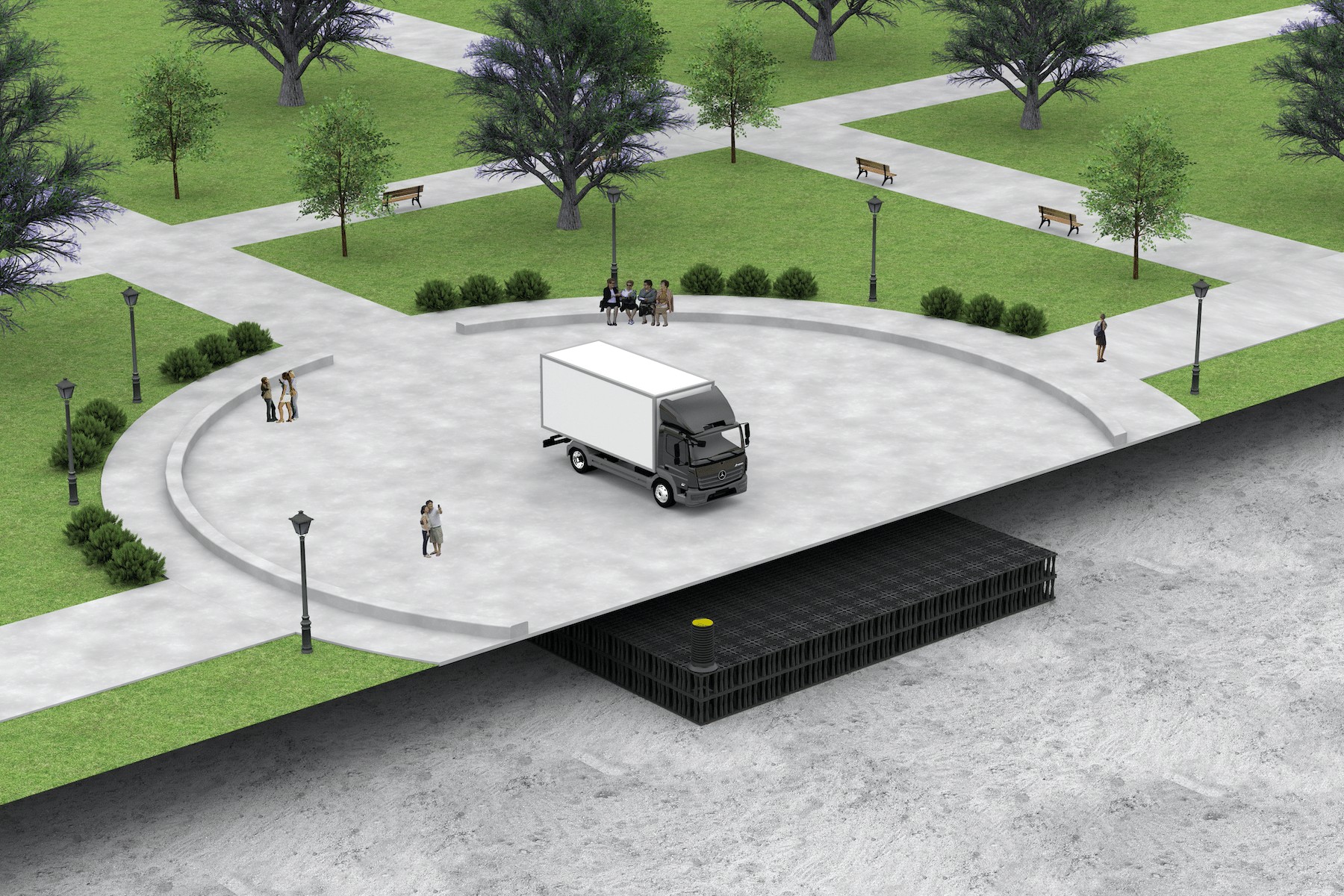

Thanks to the maximum installation depth of 4.00 metres, resistance to medium-heavy traffic loads (SLW 30) and the possibility of combining various modules, the optimum infiltration or buffer storage facility can be created for every situation. The Rigofill ST-B module is made of recycled polypropylene (PP) and has a minimum service life of 50 years.

100% inspection and cleaning

It also has the advantage of being the most easily accessible infiltration system with complete inspection visibility on the market. The complete pillar construction relevant for statics, the geotextile sheathing of the sidewall grids and the whole floor can be completely inspected and serviced. You can thus rely on the maximum capacity for the whole service life of the infiltration system.

Complete accessibility

The QuadroControl inspection shaft can be completely integrated into the Rigofill ST-B infiltration system. The access shaft has an inside diameter of 500 mm, thus making inspection and/or cleaning quick and efficient. With the use of an integrated QuadroControl inspection shaft, you can eliminate the need for a separate inspection shaft (installed outside the system) and make the whole system easy to inspect and clean at lower cost.

Cost saving

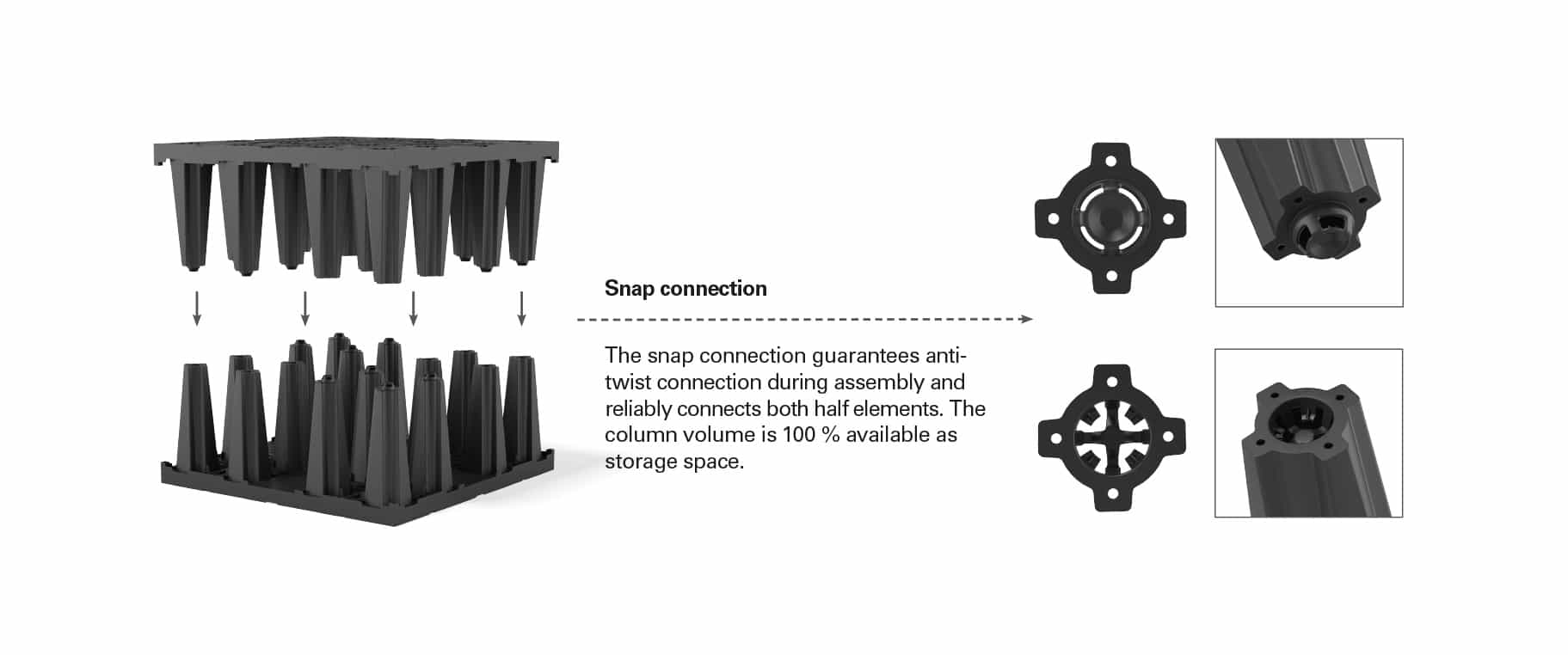

Cost saving 1: Faster installation

The Rigofill ST-B system is installed approx. 40 % faster than a normal modular system That guarantees significant savings in the installation costs.

Cost saving 2: Less heavy material

A crane is required only on delivery of the pallets with the materials to or alongside the installation shaft for positioning of the modules.

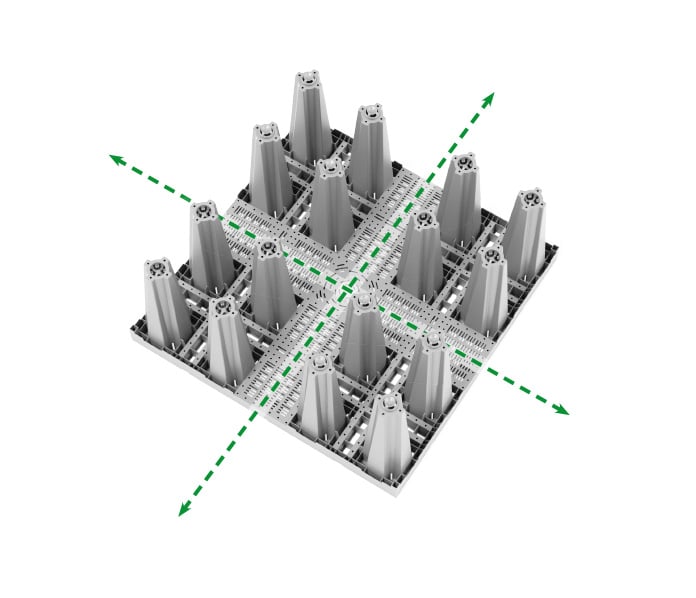

Cost saving 3: Less storage space on site

The Rigofill ST-B modules are delivered on pallets. (800 modules/338m3 on 1 truck). As a result, 75 % less space is required on site – an enormous advantage particularly in busy urban areas.